Gunnison Copper is located in an arid climate where water is a limited resource. All users – industry, utilities, agriculture and people – must seek ways to protect both the quality and quantity of water.

Modern in-situ methods and technologies have been proven to fully protect groundwater quality. In fact, demonstrating that the Gunnison Copper Project will not contaminate adjacent groundwater is the primary component for acquiring the necessary permits to go into production.

Ensuring water integrity starts with the physical construction of the delivery and recovery wells. Each well is encased within several layers of protective casing, including acid-resistant cement on the outer layer, to safeguard against the possibility of any leaks. The wells are pressure tested before extraction can commence, and follow up pressure tests are conducted at regular intervals during the life of mine. Each well is also fitted with an electronic real-time leak detector.

During the extraction process, water is pumped from a row of recovery wells (hydraulic control wells) that line the outside of the entire well field. This pumping creates a low pressure zone around the extraction area that causes the surrounding water to flow inwards, towards the extraction area. This inward water flow restricts any acid from escaping beyond the immediate area of extraction. This process allows Gunnison Copper to maintain hydraulic control over fluids during extraction and reclamation.

The process of hydraulic control is very common and used throughout the world as the standard operating procedure for environmental remediation. Regulatory agencies prefer the system of hydraulic control as the best way to both contain and prevent solutions from mixing with nearby groundwater systems. This procedure is not specific to in-situ, nor is it specific to extraction. Hydraulic control is the global standard for the prevention of water contamination.

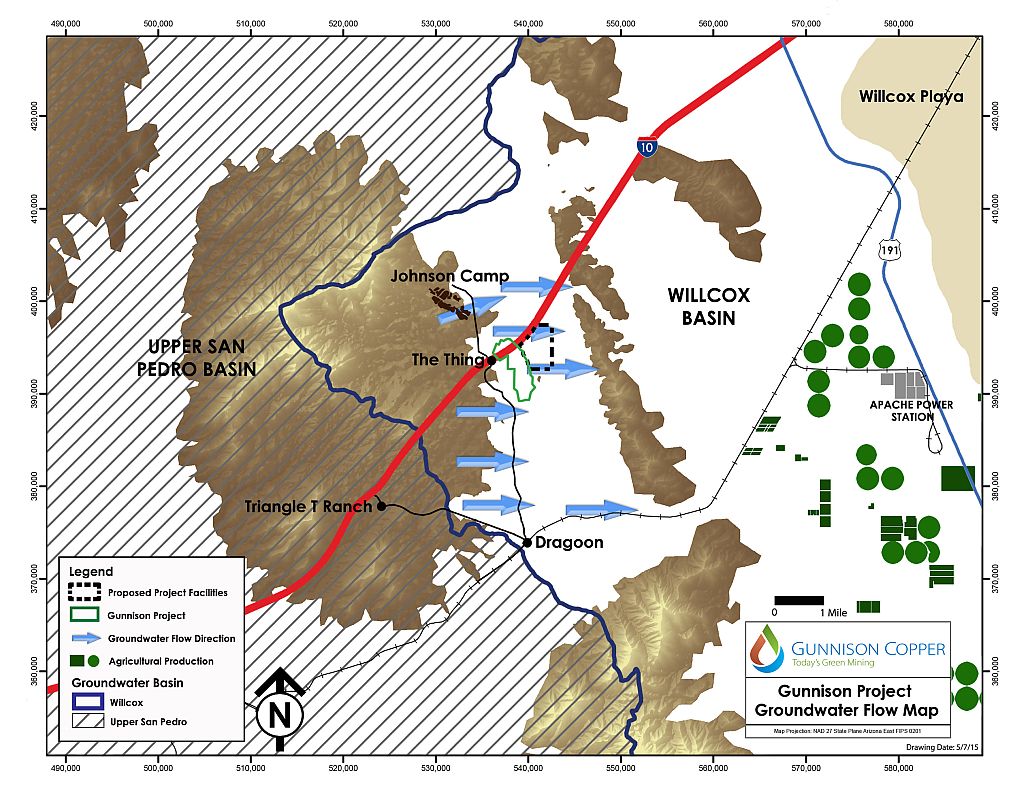

The unique geology and position of the copper deposit provides an additional environmental safeguard. The deposit is surrounded in rocks that are natural acid consumers. Furthermore, the rock formations to the east of the deposit are dominated by large amounts of carbonate, which neutralizes acid. Groundwater flow in the Willcox Basin runs West to East. These acid-neutralizing limestone formations sit directly in the path of any groundwater flow moving east from the deposit. Again, the formations will naturally buffer any itinerant solutions and make the process of restoration easier. The Gunnison Copper Project will not contaminate any existing water wells or the groundwater in the Willcox Basin.

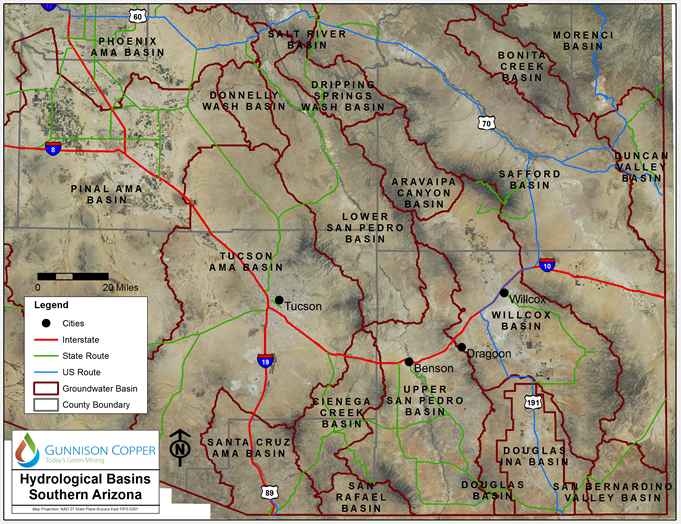

The Location of the Willcox Basin

Gunnison Copper will construct a state-of-the-art water treatment facility on site, which uses reverse osmosis, acid neutralization, and micro-filtration to clean extraction solutions from the water before returning them to the aquifer. Projected water use will make Gunnison Copper one of the most water efficient copper extraction operations in the State. The Gunnison Copper team continues to study methods for reducing its water consumption even further.

Groundwater Flow Map